Visit www.excelnex.com

|

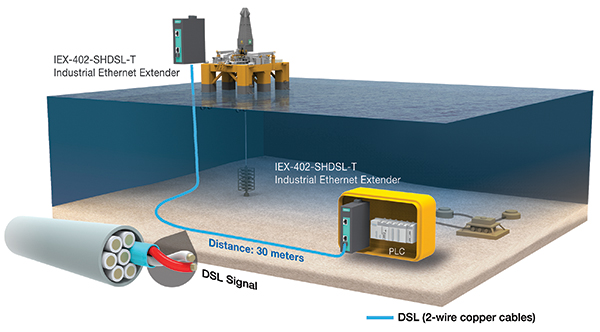

Building a Subsea Oil & Gas Control Application with Industry-Specific Cables

For subsea control applications, great efforts are made to install industry-specific cables under the sea. In this project, the number one requirement is to leverage the existing infrastructure to reduce costs and time spent on installing cables. In addition, oil & gas environments are extremely hazardous due to the high pressures the products are subjected to, so the installation has to be quick and must support remote management and diagnosis. • Utilize existing industry-specific wires under the sea to lower the risk of damaging cables • Easy installation, diagnosis, and management • Reliable operation in harsh environments

IEX-402-SHDSL Series Features: • The IEX-402 allows users to extend Ethernet over existing industry-specific cables • Easy installation with auto CO/CPE negotiation • -40 to 75°C wide operating temperature range and rugged design for harsh environments |

|||||

|---|---|---|---|---|---|

About ExcelNex I Products I Contact I Sitemap |

ExcelNex Integrated Sdn Bhd I Tel: (KL) +603-5636 0306 (PG) +604-641 5306 |