Ensure Seamless Integration and Reliable Performance With Our CANbus Solutions

Modern industrial applications require robust and effective communication. Our complete range of CANbus products guarantees smooth integration and data transfers throughout your systems. We offer CAN protocol gateways for converting protocols, CAN-to-fiber converters for extended range and better signal quality, and CAN serial cards for versatile connectivity. Take a look at the case studies below to see how our products are practically applied and the benefits they offer. Explore these examples to understand how our solutions can support and enhance your CANbus communication needs, ensuring reliable performance in different industrial environments.

CAN Protocol Gateways

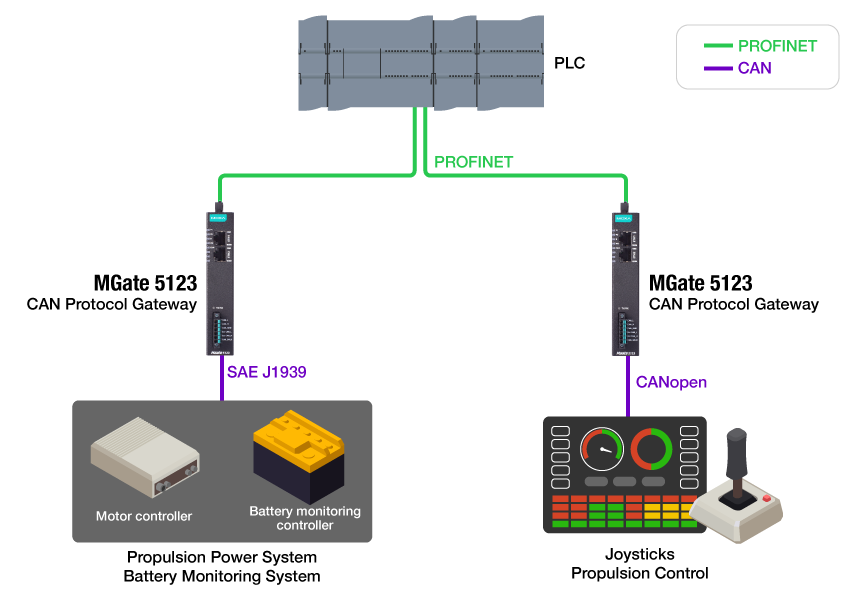

Ship Integrated Electric Propulsion System

System Requirement

- To address environmental concerns, modern marine propulsion systems are incorporating batteries, requiring the connection of devices between the bridge and the propulsion system to the PLC for control.

- The devices are using various protocols, such as J1939 (battery), intelligent joysticks (CANopen), and PLC (PROFINET), which require protocol conversions.

- Because of limited space in the electrical cabinet, the protocol gateway must be smaller.

Why Moxa

- The MGate 5123 is flexible, supporting J1939 or CANopen for end devices and converting to PROFINET for PLC.

- Compact design to fit in limited installation spaces.

- Integration of heterogeneous systems is sped up with built-in protocol diagnostics, traffic monitoring, and event logging for efficient troubleshooting.

| Series | MGate

5122 |

MGate

5123 |

|

| Northbound Protocol | Modbus TCP SNMP |

EtherNet/IP SNMP |

PROFINET SNMP |

|---|---|---|---|

| Southbound Protocol | CANopen, SAE J1939, CAN 2.0A/B* | ||

| Operating Temperature | Standard: -10 to 60°C Wide: -40 to 75°C |

||

*CAN 2.0A/B will be supported with firmware update by Q4, 2024

CAN-to-fiber Converters

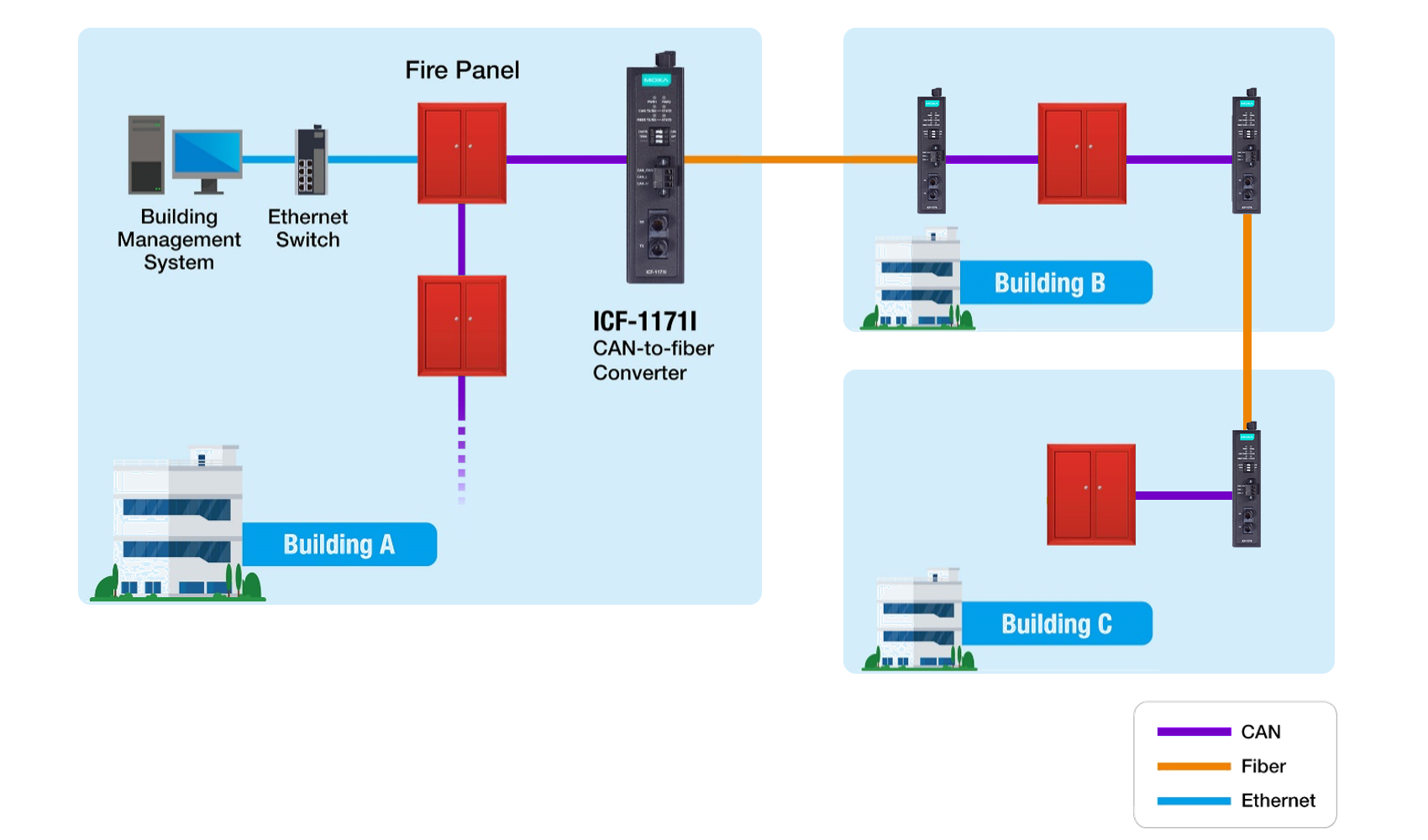

Fire Alarm System

System Requirement

- Baudrates limit CAN bus communication distances. The higher the baudrate, the shorter the communication distance. CAN-to-fiber converters extend communication distances of fire panels between buildings.

- The ACK mechanism of the CAN-to-fiber converter is a must.

-

Why Moxa?

- Supports CAN baudrate up to 1 Mbps and CAN FD baudrate up to 5 Mbps; fiber transmission distance can be extended up to 40 km using single-mode, or 2 km using multi-mode

| Series | ICF-1170I |

|

| Positioning | Signal Isolation Only | Distance Extension |

|---|---|---|

| Protocol Support | CAN | CAN, CAN FD |

| Fiber Mode | Multi-mode (distance up to 2km) |

Multi-mode and Single-mode (distance up to 40 km) |

| Auto Baudrate Function | - | ✓ |

| Operating Temperature | Standard: 0 to 60°C Wide: -40 to 85°C |

Standard: 0 to 60°C Wide: -40 to 75°C |

CAN Interface Cards

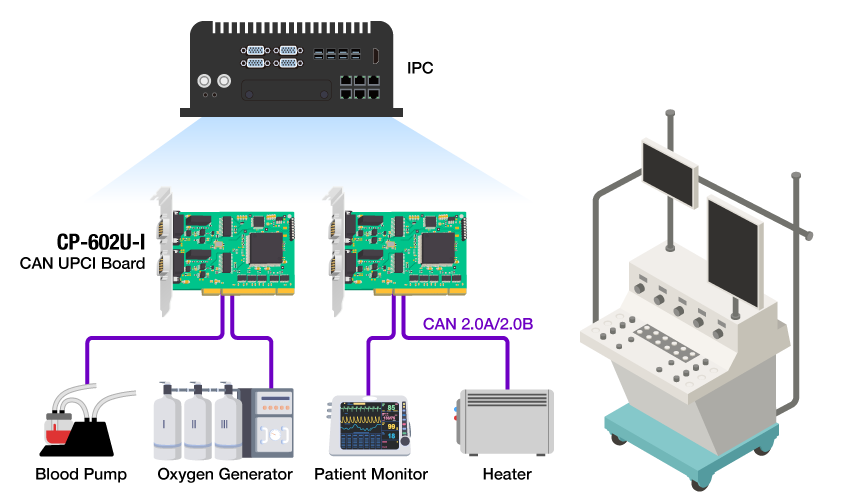

Heart-lung Machine System

System Requirement

- A medical components provider is using CAN interface for reliability and effectiveness, especially for heart-lung machines

- Most medical equipment uses Industrial PC to integrate the device and develop application, and might involve modular design

- The medical machine cabinet space is constraint

Why Moxa

- Machine Maker can insert Moxa CAN card into the box-type IPC to easily integrate the CAN interface on their IPC system.

- Moxa’s commitment to developing drivers that support various IPC OS ensures customers can easily integrate CAN cards into their systems regardless of the OS types, legacy or modern platforms.

| Series |

CP-602E-I

|

CP-602U-I

|

CB-602I

|

|---|---|---|---|

| Interface | PCI Express | Universal PCI | PC/104-Plus |

| Protocol | CAN 2.0A, CAN 2.0B | ||

| Baudrate | 10/20/50/125/250/500/800/1000 kbps, user-defined | ||

| Isolation | 2kV | ||

| Operating Temperature | Standard: 0 to 55°C Wide: -40 to 85°C |

||