Data Acquisition / Compact Remote I/O / ioLogik E1213

ioLogik E1213

Ethernet Remote I/O with 2-port Source Type Ethernet switch and 8 DIs, 4 DOs, and 4 DIOs

Features and benefits:

- Active communication with patented Active OPC Server

- 2-port Ethernet switch for daisy-chain topologies

- Easy mass deployment and configuration with ioSearch utility

- Save time and wiring cost with peer-to-peer communication

- User-defined Modbus/TCP addressing

- Simplify I/O managment with MXIO library on either Windows or Linux platform

- Supports SNMPv1/v2c

- UL/cUL Class I Division 2, ATEX Zone 2 certification

- Wide operating temperature: -40 to 75°C ( -40 to 167°F )

Certifications

DATASHEET DOWNLOAD GET A QUOTE

Introduction

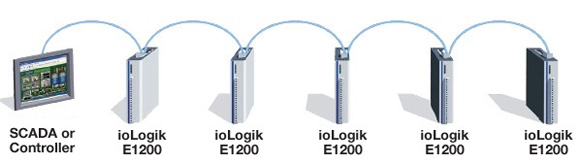

Daisy-chained Ethernet I/O Connection

A

new daisy-chained Ethernet I/O concept is now available. The ioLogik E1213 industrial Ethernet remote I/O has

two embedded Ethernet switch ports that allow information to flow to another local Ethernet device or connect

to the next ioLogik in the daisy-chain.

A

new daisy-chained Ethernet I/O concept is now available. The ioLogik E1213 industrial Ethernet remote I/O has

two embedded Ethernet switch ports that allow information to flow to another local Ethernet device or connect

to the next ioLogik in the daisy-chain.

Applications such as factory automation, security and surveillance systems, and tunnel monitoring, can make use of daisy-chained Ethernet for building multi-drop I/O networks over standard Ethernet cables. Many industrial automation users are familiar with the multi-drop configuration typically used in fieldbus applications. The daisy-chain function on the Ethernet remote I/O ioLogik E1213 not only increases the connection between machines and panels, but also lowers the cost of buying separate Ethernet switches, and at the same time reduces labor fees and cabling by a large percentage. For example, if a production facility contains 700 stations (20 points per station), the wiring cost reduction can reach 15% of the total implementation cost.

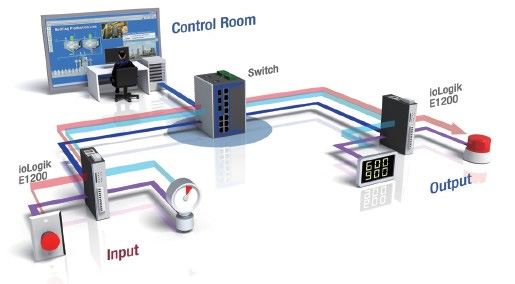

Saving Time and Wiring Costs with Peer-to-Peer Communications

In remote automation applications, the control room and sensors are often far removed, making wiring over long distances a constant challenge. With peer-to-peer networking, users may now map a pair of ioLogik E1200 series modules so that input values will be directly transferred to output channels, greatly simplifying the wiring process and reducing wiring costs.

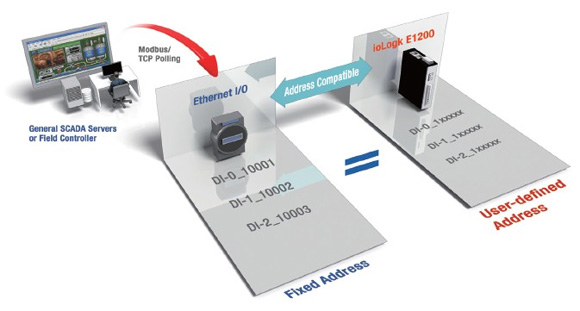

User-definable Modbus/TCP Addressing for Painless Upgrading of Existing Systems

For Modbus devices that are controlled and detected by fixed addresses, users need to spend a vast amount of time researching and verifying the configurations. Users need to locate each device’s networking details like I/O channels, or vendor-defined addresses to enable the initial or start address of a SCADA system or PLC. The ioLogik E1200, with user-definable Modbus/TCP addressing, offers greater flexibility, and setup is easy. Instead of worrying about individual devices, users simply configure the function and address map to fit their needs.